Contrasting Different Versions of Galvanometer Scanners for Ideal Performance in Labs

Contrasting Different Versions of Galvanometer Scanners for Ideal Performance in Labs

Blog Article

Comprehending the Uses of a Galvanometer Scanner in Precision Measurement Applications

Galvanometer scanners have actually arised as crucial tools in accuracy measurement applications, particularly due to their amazing capacity to adjust laser beam of lights with exceptional rate and precision. Recognizing the functional technicians and diverse applications of these scanners exposes not only their value however likewise the advantages they confer in preserving industry standards.

Exactly How Galvanometer Scanners Work

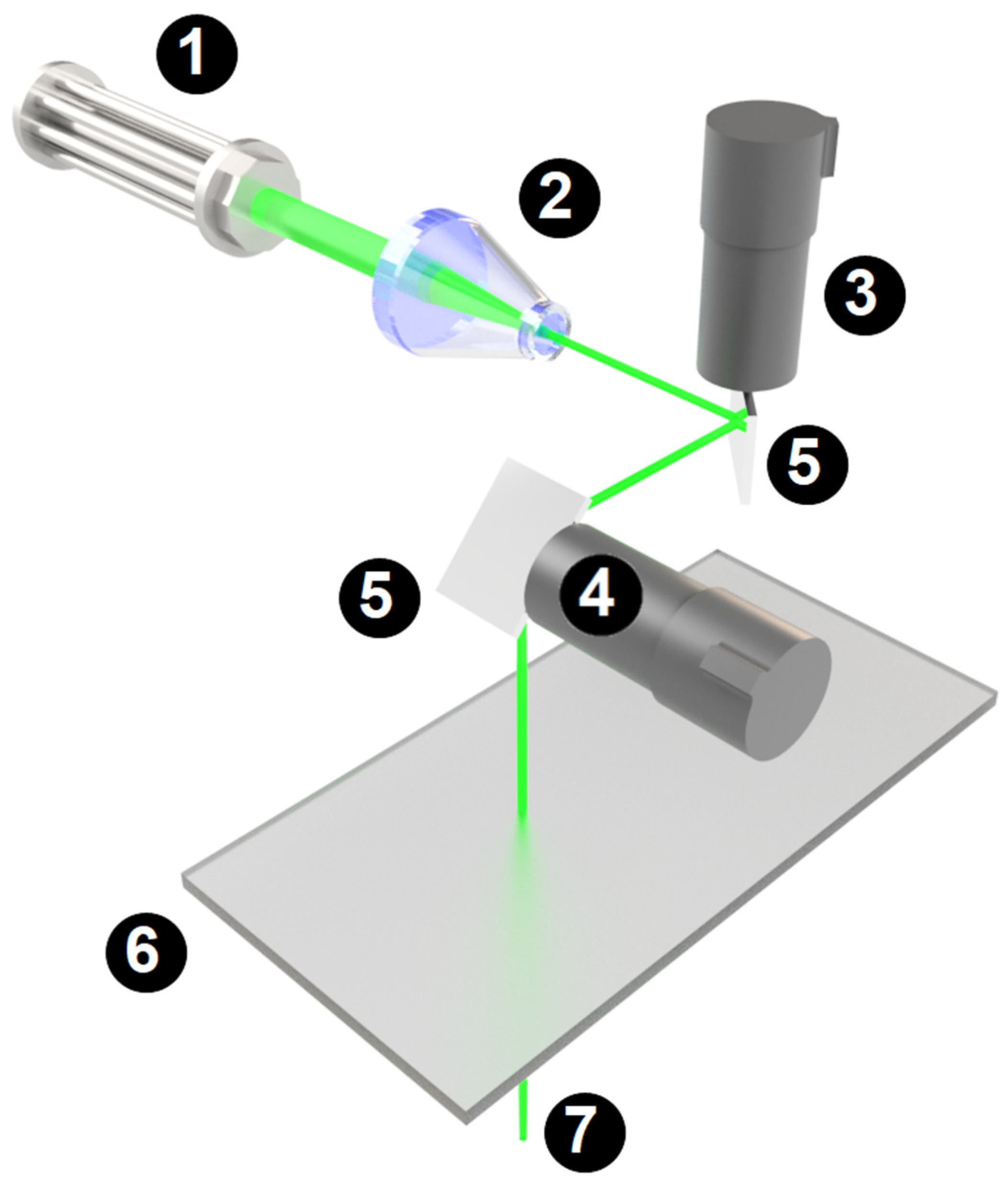

A galvanometer scanner operates by using the principle of electromagnetic deflection to manage the placement of a light beam. This gadget includes a coil put on hold in an electromagnetic field, where electric currents travelling through the coil develop a torque that creates it to turn. The angle of deflection is proportional to the existing, permitting specific control over the beam's setting.

Commonly, galvanometer scanners utilize a combination of mirrors and lenses to guide the beam throughout a wanted surface area or tool - galvanometer scanner. The fast action time of the galvanometer enables high-speed scanning and exact placing, making it suitable for various applications. The comments mechanism, often incorporated into the system, ensures that the beam of light stays aligned with the desired target by readjusting the present based upon the actual deflection angle

The construction products and layout of the galvanometer, consisting of the coil resistance and the stamina of the electromagnetic field, are important variables that affect its performance. These elements add to the scanner's sensitivity, resolution, and overall functional efficiency. Comprehending just how galvanometer scanners job is essential for enhancing their use in accuracy dimension applications.

Applications in Laser Scanning

Galvanometer scanners play a crucial duty in laser scanning applications, where accuracy and rate are vital. These tools make use of a turning mirror system to route laser beams with high precision throughout different surface areas, making them essential in fields such as material handling, 3D scanning, and laser noting. The capacity of galvanometer scanners to accomplish rapid angular motion enables effective raster scanning, which is vital for developing in-depth and high-resolution pictures.

In commercial settings, galvanometer scanners contribute in laser cutting and engraving, where they give repeatable and constant control over the laser beam of light's setting. This ability guarantees that complex layouts can be executed with marginal errors, improving production quality. Moreover, in the world of 3D laser scanning, these scanners assist in the capture of complex geometries by quickly brushing up the laser light beam over an object, generating exact factor clouds for digital modeling.

Additionally, the combination of galvanometer scanners in laser screen technologies showcases their flexibility. They allow the development of vibrant visual effects in home entertainment and advertising and marketing, additional illustrating the relevance of accuracy in laser scanning applications across diverse industries.

Function in Biomedical Imaging

Making use of galvanometer scanners in biomedical imaging considerably boosts the precision and speed of information acquisition in various medical applications. These scanners facilitate accurate and rapid positioning of laser beam of lights, which is crucial for high-resolution imaging strategies such as optical coherence tomography (OCT) and confocal microscopy. By employing galvanometer scanners, health care specialists can get in-depth cross-sectional photos of cells, permitting very early medical diagnosis and effective surveillance of conditions.

Along with improving image high quality, galvanometer scanners contribute to the performance of imaging treatments. Their capability to swiftly and precisely direct laser beams lessens motion artifacts, improving the reliability of the data gathered. This is particularly vital in dynamic atmospheres where patient motion might compromise image integrity.

Moreover, the adaptability of galvanometer scanners to various wavelengths and imaging methods makes them integral to advanced biomedical research. They can be made use of in fluorescence imaging, enabling scientists to examine mobile processes and molecular interactions you could try these out with unmatched clearness. As the area of biomedical imaging proceeds to evolve, check these guys out the role of galvanometer scanners will certainly remain critical in driving advancements that improve diagnostic capabilities and boost client outcomes.

Significance in Industrial Processes

Additionally, galvanometer scanners are vital in optical inspection systems, where they allow real-time monitoring of assembly line. By quickly scanning products for issues, these systems help maintain rigid quality control criteria, guaranteeing that just products fulfilling requirements proceed to the following phase of manufacturing. Additionally, in the world of 3D printing, galvanometer scanners add to the precision of layer deposition, significantly affecting the last product's precision and structural honesty.

In industries such as electronic devices and vehicle, the ability to execute exact dimensions and changes in real-time translates to boosted efficiency and performance. Subsequently, the application of galvanometer scanners not only improves functional capabilities but additionally plays an important duty in driving innovation throughout various industrial sectors.

Benefits of Precision Measurement

Accuracy dimension is a cornerstone of contemporary commercial operations, offering various benefits that can dramatically enhance item quality and operational efficiency. By guaranteeing that dimensions are precise and consistent, companies can minimize irregularity in manufacturing procedures, leading to more uniform items. This harmony not just meets client assumptions but additionally like it reduces waste, as less faulty items make it to the last phases of production.

Additionally, accuracy measurement facilitates compliance with industry criteria and regulations. Precise measurements are critical for fulfilling security and quality criteria, which can safeguard services from pricey fines and reputational damages. The usage of sophisticated dimension innovations, such as galvanometer scanners, enables quick data purchase and evaluation, additional simplifying procedures.

On top of that, precision dimension boosts decision-making capacities within organizations. By supplying reputable data, it permits for notified critical preparation and source appropriation. In a competitive market, these advantages can bring about increased productivity and market share.

Ultimately, the combination of accuracy dimension into commercial operations is not merely an option; it is a necessity for services looking for to thrive in a significantly requiring environment. galvanometer scanner. The advantages expand past immediate gains, positioning companies for long-term success

Conclusion

To conclude, galvanometer scanners work as vital instruments in accuracy dimension applications, boosting the precision and rate of laser beam control across different markets. Their integration into procedures such as laser cutting, marking, and biomedical imaging highlights their importance in enhancing operational performance and making certain compliance with industry standards. The benefits used by these scanners, including minimized irregularity and enhanced data procurement, emphasize their vital function beforehand innovation and fostering innovation in open markets.

Galvanometer scanners have arised as crucial devices in accuracy dimension applications, specifically due to their exceptional capability to manipulate laser beams with outstanding rate and accuracy.Galvanometer scanners play a crucial duty in laser scanning applications, where precision and speed are critical.In commercial settings, galvanometer scanners are important in laser cutting and inscription, where they supply regular and repeatable control over the laser beam of light's position. In laser machining, galvanometer scanners direct laser beam of lights with outstanding accuracy, facilitating complex cutting, engraving, and marking tasks.In final thought, galvanometer scanners serve as crucial instruments in accuracy dimension applications, boosting the precision and speed of laser light beam control across different sectors.

Report this page