3 Easy Facts About Premier Aluminum Llc Described

3 Easy Facts About Premier Aluminum Llc Described

Blog Article

Getting My Premier Aluminum Llc To Work

Table of ContentsThe 2-Minute Rule for Premier Aluminum LlcThe smart Trick of Premier Aluminum Llc That Nobody is Talking AboutHow Premier Aluminum Llc can Save You Time, Stress, and Money.Premier Aluminum Llc Fundamentals Explained

(https://www.brownbook.net/business/53359936/premier-aluminum-llc/)Using low price and unqualified distributors can cause top quality problems, and wasted time and cash in the lengthy run. To help you through the process, right here are some things to consider when selecting the best metal spreading supplier.

A company that only uses the investment casting procedure will attempt to market you on why that procedure is best for your application (Aluminum Foundry). Yet what happens if utilizing the sand spreading procedure is best for you and your requirements? Instead, try to find a distributor that uses a variety of casting procedures so the best option for YOU is chosen

If dealing with a solitary resource for all of your spreading requires is necessary to you, the distributor needs to be diverse in its abilities. When integrated with various other integrated capabilities, this can aid streamline and press the supply base. When selecting the best casting distributor, cautious factor to consider ought to be offered to high quality, service, and cost.

Some Known Factual Statements About Premier Aluminum Llc

Purchasers significantly choose spreading distributors that have machining capacities. If the spreading provider finds an issue throughout machining, the problem is dealt with much faster with no dispute over whose mistake it is.

What do you need from your spreading provider? Are you looking for a person to click over here simply provide a metal element to your front door or do you need much more?

Others will exceed the letter of the PO to aid you conserve money and time. Do you have demands for both ferrous and non-ferrous alloys? Some factories are minimal or specialized. See to it the provider can meet all your material or alloy needs to eliminate the need for multiple suppliers.

Premier Aluminum Llc Can Be Fun For Anyone

Research study the distributor's website. Talk to a sales associate or company associate.

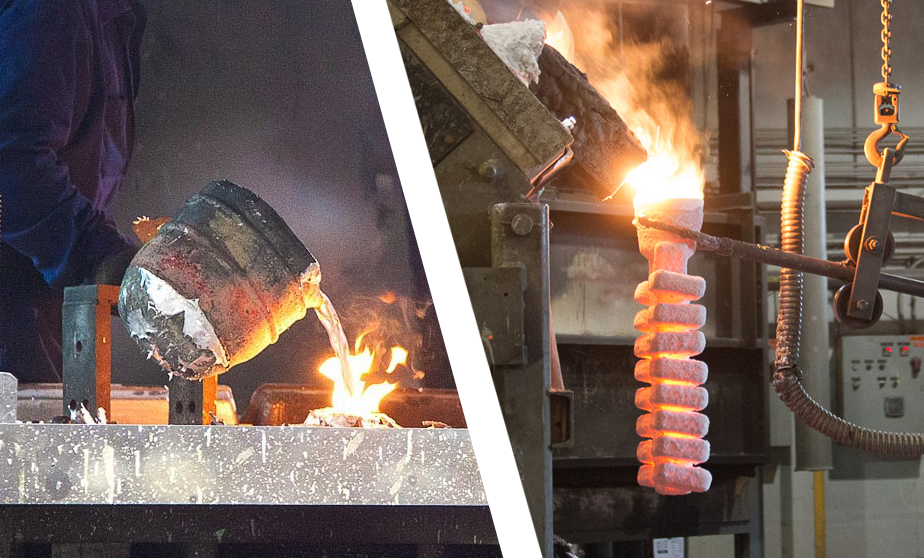

Light weight aluminum is likewise light-weight and has great corrosion resistance, making it perfect for applications where weight and resilience are vital factors. Additionally, light weight aluminum spreading is an affordable method of manufacturing, as it needs much less energy and sources than other techniques. Iron spreading, on the various other hand, entails putting liquified iron right into a mold to create a desired shape.

Top Guidelines Of Premier Aluminum Llc

Iron casting is also able to hold up against heats, making it suitable for use in applications such as engine components and industrial machinery. Nevertheless, iron spreading can be much more costly than aluminum casting due to the higher cost of raw materials and the energy needed to melt the iron. When deciding in between aluminum casting and iron casting, it is essential to consider the specific needs of the application.

In final thought, both aluminum casting and iron casting have their very own special benefits and negative aspects. There are 3 sub-processes that drop under the group of die casting: gravity die spreading (or permanent mold and mildew casting), low-pressure die casting and high-pressure die casting. To obtain to the ended up product, there are 3 key alloys used as die casting material to pick from: zinc, light weight aluminum and magnesium. Report this page